Alhamdulillah. The Wind Turbine Generator in Train System project was successfully done. I would like to thank my supervisor, Mr. Syamsul Adlan Bin Mahrim for his commitment, responsibility, supports and guidance in assist me through every stage of this project. It was a great journey to be under your supervision and doing this project. Thanks to those who read this blog! :)

Saturday, 17 November 2012

Wednesday, 7 November 2012

Tuesday, 6 November 2012

Saturday, 3 November 2012

Final prototype of Wind Turbine Generator in Train System

Final prototype

Labeling

of prototype

Labeling

of prototype is very important to every project. It is because from the

labeling the prototype looks more tidy and proper. Besides that, it is easier

for people to see clearly what is on the prototype.

Tuesday, 30 October 2012

Results

Project Description

•

Wind charger is

operating using 12V battery. This system is using LCD to show wind generator

and battery voltage. When the battery voltage is low, motor will charge the

battery.

•

When system is

operating, voltage sensor detect wind generator voltage and show on LCD.

Voltage sensor detects battery voltage. If battery voltage more than 12V, green

LED will turn on. Else, red LED will turn on. Battery voltage will show on LCD.

Condition : Battery is charging.

Yellow LED indicates system runs, red battery is not full and green for

charging the battery.

Condition : Battery is not charging.

Yellow LED indicates system runs, green LED for battery is full.

Wednesday, 17 October 2012

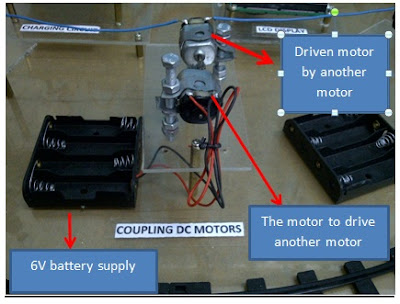

Coupling DC motors

· Voltage produced

by a single motor with wind turbine is not sufficient enough to charge up 12V

DC battery.

· In this case coupling DC motors are introduced. There are six numbers of couplings that are being connected in series connection to get higher voltage. Need a motor with battery supply of 6V to drive another motor. In this case it became DC generator. The motor that is used to drive is a replacement of wind source.

· By using this method, the motor that is driven will produce higher voltage which is approximately 1.5V each coupling compared to a single motor with wind turbine which only produce only 0.14V.

· The reason why

every coupling has its own battery supply of 6V instead of using one supply to

all six couplings is because voltage drop does not occur. Using one supply to

all six couplings will produce voltage drop and in this case some of the motors

do not have sufficient voltage to drive another motor.

Saturday, 13 October 2012

Making platforms for project components

Prospect is used as the platform to install the project components. By using this prospect, the prototype will look more tidy and proper. Pictures below shows the process of cutting prospect.

Examples of platforms for components by using prospect

For coupling DC motors

For DC motor with wind turbine

For switch on/off and LEDS

For charging circuit

For LCD display

Saturday, 6 October 2012

How to make wind turbine blades

The

easiest object that you can find to make wind turbine blades is by using drink can.

The main reason why drink can is being chose at the first place is about the

material which is light in weight. Because of this the wind turbine can spins

smoother and easier. Besides that, the material is flexible. Flexible in this

case means to shape something. The wind turbine needs to be airfoil in shape.

Because of this airfoil shape, it will be easier for the wind turbine to spin

when there is wind energy source. A can of drink normally would cost you only

RM1.50 and you it can be found anywhere. It is good to use recycle items to

make something useful out of it. Below shows the steps in order to make wind turbine blades:-

Sunday, 30 September 2012

Source code for Wind Turbine Generator in Train System

***coding for charging circuit

#include <16F877a.h>

//use pic16f877a

#device adc=10 //use

10bit adc detect bat voltage

#use delay(clock=20000000) //clock speed=20mhz

#fuses hs,noprotect,nowdt

//default setting

#define use_portb_lcd TRUE //use portb for lcd

#include <lcd.c>

//call lcd.c library

//enable port a, b, c, d, e

#byte PORTA=5

#byte PORTB=6

#byte PORTC=7

#byte PORTD=8

#byte PORTE=9

long int adc1;

long int adc2;

int mycount=40;

float mybat, mywind;

void main()

{

//initialize system

set_tris_a(0b11111111);

set_tris_b(0b00000000);

set_tris_c(0b00000000);

set_tris_d(0b00000000);

set_tris_e(0b00000000);

setup_port_a(ALL_ANALOG);

setup_adc(ADC_CLOCK_INTERNAL);

output_low(pin_d2); //stop

charging

output_high(pin_d5); //on green led

output_high(pin_d4); //on red led

delay_ms(1000);

output_low(pin_d5);

//off green led

output_low(pin_d4);

//off red led

lcd_init();

lcd_putc("\f");

do

{

if(mycount==40)

{

mycount=0;

//cutoff

charging

output_low(pin_d2);

delay_ms(200);

//read solar

volt

set_adc_channel(0);

delay_ms(10);

adc1=read_adc();

mywind=adc1/65.41;

delay_ms(10);

//read battery volt

set_adc_channel(1);

delay_ms(10);

adc2=read_adc();

mybat=adc2/65.41;

delay_ms(10);

//display

output

printf(lcd_putc,"\fB:%.2f W:%.2f ",mybat, mywind);

if(mybat<12) //if battery <

12V

{

output_low(pin_d5); //off green led

output_high(pin_d4); //on red led

output_high(pin_d2); //charge

battery

printf(lcd_putc,"\nBat Charging

");

}

else //if battery >= 12V

{

output_high(pin_d5); //on green led

output_low(pin_d4); //off red led

output_low(pin_d2); //stop charge

battery

printf(lcd_putc,"\nBat

Not Charging");

}

}

else

{

mycount=mycount+1; //increase

counter

}

delay_ms(250);

}while(1);

}

Schematic diagram for Wind Turbine Generator in Train System

Schematic diagram

Schematic diagram explainations

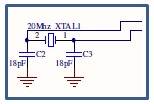

1) 20

MHz crystal

· 20 MHz crystal is used in order to enable the PIC to execute

every single program line in the system

· 20 MHz crystal is used because this is

the maximum frequency that the PIC

can support. If the speed is less than 20 MHz then the PIC response speed will

be slower.

· If over frequency the PIC will burn.

2) Voltage

regulator LM7805

· To protect PIC

and other connected sensors / actuators from over voltage (maximum 5V).

· It supports input voltage from 7V DC to

18V DC. If the input voltage is over, the LM7805 will burn or auto shutdown due

to overheat.

· The generated 5V from LM7805 will be

noise filtered by 0.1uF ceramic capacitor and a 1000uF electrolytic capacitor.

This is to avoid high frequency oscillation on the outputs which may cause

system hang or unstable.

· A diode is connected at the input of the

LM7805. This is to avoid voltage connected reversely.

· The power LED is used to indicate the

system is ‘ON’/running.

3) Relay

(5V Relay-SPDT)

· A relay is used to start or stop charging the operation. This relay is controlled by PIC microcontroller. Whenever the charging operation is

running, a LED indicator will turn on else the LED indicator will turn off.

4) PIC16F877A microcontroller

· PIC16F877A microcontroller is used to

control the whole system.

· Port A is used for input. The inputs are

from battery and motor.

· Port B is used for LCD display.

· Port D is used for outputs. There are

three LEDs used as indicators. The red LED at pin RD4 is used to show battery

voltage less than 12V or not fully charge. The green LED at pin RD5 is to

indicate when the battery is full while the green LED at pin RD2 is to show

battery is charging.

5) LCD display

· · LCD display is used to show the wind

generator and battery voltage.

6) Diode

(lN 4007)

· Diode is used to make sure current flows

in one way. This is to prevent the current to go reverse and hence can damage

the components.

Sunday, 16 September 2012

Procedure for PCB design

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Step 10

Step 11

Step 12

Step 13

Step 14

Step 15

Subscribe to:

Comments (Atom)